These are unprecedented times with runaway inflation, supply chain issues, labor shortage, and continued impacts from the global pandemic. As a business leader, you need to accelerate the changes that are going to make your company more competitive and resilient in a world of constant change. You have been on the path to digitize your business as one clear strategy to help meet these needs. Yet progress has likely been slow-to-date – especially for internal teams like your maintenance operations. It’s time to take a new approach.

In today’s article, we are going to highlight how to drive the digital transformation in SAP-based operations to support a more lean and agile organization while minimizing the resource impact to your IT department.

Digitization in Enterprise Asset Management

“The “new normal” is disruption. Organizations that lean into this reality and leverage their innovation capacity, technology and reach will not only survive, but grow as a result.”

Monika Sinha, VP Analyst, Gartner

In every facet of your business, you are having to constantly adjust to change driven by the pandemic, supply chain shortages, labor shortage and now unprecedented growing inflation. Technology is a key enabler of dealing with change, but with tight IT resources it is harder than ever to both accelerate and scale technology adoption across your business.

According to McKinsey in the report: Navigating inflation: A new playbook for CEOs, a key concern for CEO’s is “What is the fastest way to stabilize, and redesign stretched and, in some cases, broken supply chains? What capabilities will I need to increase my company’s resilience and control costs?… The good news is that digitalization will likely play an important role in answering these questions, and digital efforts often pay back their costs in 12 months.”

In other words, digital readiness is key for every facet of the organization including your operations teams.

The Imperatives for CIOs

Times are different, but the story is the same, digitization across your business will increase collaboration, efficiency, and capture the real-time data needed to increase resilience and control costs. According to Gartner’s CIO Agenda, The leadership, organizational, and technology priorities CIOs must address in 2022, “Use technology in ways that support key pieces of composable business. Composable Technologies are systems and data that integrate quickly and easily. Highly composable organizations recognize that iterative delivery processes, collaborative workstyles, and integrated systems drive better results.”

The CIO challenge is to put in place the technology infrastructure to enable this rapid composing of new products, new production methods, and new ways of collaboration to execute changes quickly and efficiently to stay competitive. This means that IT needs to accelerate digital initiatives, overcome historical roadblocks to progress, and do so with fewer IT resources.

How? Here’s a few strategies that are proving successful in today’s environment:

1) Democratize IT

The concept is simple, share the workload. How? Low-code and no-code tools are increasing efficiency for IT and the organization as a whole. Anyone in the business can collaborate with IT to digitize processes and collaborate to create better results.

“Who knew that one day, ordinary citizens, who lack deep knowledge of technology and programming, would be able to create really efficient solutions for their daily processes in an objective and clear way – and better: without relying on IT specialists? That’s what Low-Code provides: simplified access to technology.”

Mario Trentim, Low-Code Tools: Simplifying Technology as the Secret to Digital Transformation>, June 2022

These low-code and no-code tools are becoming increasingly available as standalone development platforms and as part of ready-made solutions. There’s many ways to start incorporating these tools sets into your development processes.

2) Start Small and Iterate

Tackle projects in an iterative approach. Agile software development methodologies have been around for a while. Now, with low-code and no-code platforms, this approach can overcome the roadblocks of past digital transformation initiatives.

“An agile transformation calls for small, specialized teams that rapidly develop experimental product iterations. Leaders establish a culture that trusts workers to experiment with creative solutions, giving them the freedom to “fail fast” and recalibrate by learning the lessons of these failures. …The value of this agile approach includes boosted workforce engagement, focused training and skill development, creative problem solving, and the ability to scale up quickly.”

McKinsey, Lighthouses reveal a playbook for responsible industry transformation>, March 2022

Besides enabling an iterative approach to each initiative, the agile approach set-ups the organization as a whole to be responsive to changes at any time.

3) Ensure Digital Readiness Across the Organization

Since digitization, collaboration, and real-time data are important for creating an organization that is adaptable and resilient to change, it is important that every group within your organization has at least achieved a baseline of replacing paper-based processes with a digital solution.

McKinsey found that the leading manufacturers were realizing significant value from Industry 4.0 technologies, but many were stuck in pilot purgatory. In their article, Capturing the True Value of Industry 4.0, April 2022, McKinsey identified several bundles of use cases that were key to success. Digital and mobile platforms for the front line workers was one bundle that was identified as a key enabler of the Industry 4.0 roadmap for business impact.

And as you know, digital transformation is more than deploying technologies, it is changing how people work, standardizing processes, and building employee skills and comfort with the use of technology. This is why digital readiness is key for every employee in the organization from the production manager to the maintenance technician.

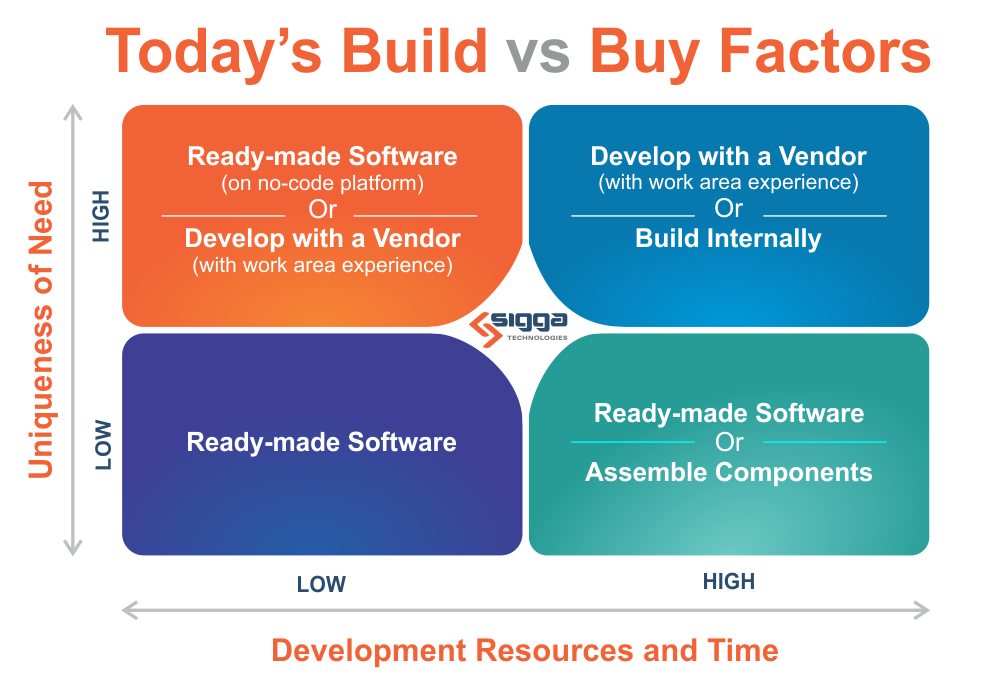

4) Balance Investments Across Digital Initiatives

Investments in technology can get ahead of where your organization is ready to embrace. New Industry 4.0 and 5.0 technologies seem to come into play almost every week. To take advantage of this technology revolution, it is important to balance and pace the investments for better return on your investment. Many Industry 4.0 technologies hold the promise of incredible savings, but only if they can be utilized.

“Formalize the value at stake. In each assessed site, describe the actual value at stake by linking the most applicable Industry 4.0 solutions or use cases with current digital readiness, data availability, and IT/OT architecture.

McKinsey, Industry 4.0: Digital transformation in manufacturing, April 2022

If a pressure sensor indicates an impending issue, how long does it take your organization to recognize the issue, create a notification, approve, and turn it into a work order, and then dispatch it to a technician for repair? Hours? Days? Weeks? How many people had to be involved? What’s the value of Industry 4.0 technologies, like sensors with real-time information, if your processes are not digitized end-to-end to be able to act in real-time?

Industry 4.0 Opportunities with the Transition to SAP S/4HANA

With the move to SAP S/4HANA, many Industry 4.0 and 5.0 use cases will become enabled using the platform’s analytics, artificial intelligence, machine learning capabilities, and databases.

“For productivity, S/4HANA includes robotic process automation tech so rote tasks can be automated, providing employees more time for higher value work for asset utilization, S/4HANA provides tools to help companies move from scheduled to predictive maintenance for more efficient equipment uptime and lower service costs for strategy, the modern ERP system includes real-time analytics features to enable data-driven decision-making.”

Jim O’Donnell, TechTarget, June, 2021

If your technicians are working with paper-based work orders which then require data entry of work status back into SAP, you won’t be able to take advantage of the power of the real-time information that SAP S/4HANA offers. This is just one of many examples for preparing maintenance operations for migrating SAP ECC to S/4HANA.

Digital Readiness for Maintenance Operations Made Easy

Here at Sigga, we have been helping asset-intensive industries mobilize maintenance operations for 20 years with a focus on SAP Enterprise Asset Management. Our software and mobile apps have been proven in use by over 70,000 technicians and are fully SAP-certified.

We understand what it takes to drive technology adoption in operations and preserve IT resources and budgets in the process. For example, our mobile EAM cloud SaaS solution comes on a no-code platform with no-code SAP integration. And, with our expertise in maintenance, we can actively drive a collaborative agile implementation and support adoption and scale across global sites.

Our Sigga EAM Empower mobile EAM application eliminates paper-based processes and digitizes the entire maintenance process connecting front-end technicians to SAP in real-time. As an outcome of implementation, the solution improves the capture, structure, and quality of your data as a baseline for taking advantage of many Industry 4.0 and SAP S4/HANA technologies.

Our integrated Planning & Scheduling desktop software provides an intuitive SAP UI5 Interface to SAP PM. This solution provides automation to drive annual budgeting, planning and regular scheduling of work orders. With the mass update feature, the solution improves data capture, structure, and data quality in SAP.

With our EAM products for SAP, your company can easily establish digital readiness within the maintenance organization. Let us help you make sure your data and processes are optimized so your maintenance operations are fully ready to take advantage of the speed, data analysis, and real-time information with current and future Industry 4.0 technologies.

Read More About Sigga and our EAM Solutions for Maintenance Operations