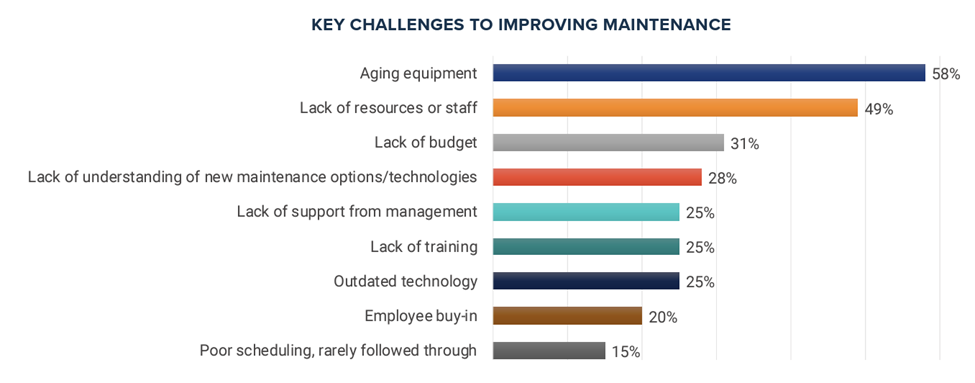

Findings from the 2022 State of Industrial Maintenance Report illustrate the importance of effective maintenance planning and scheduling. According to 58% of respondents, the top challenge to improving maintenance is aging equipment.

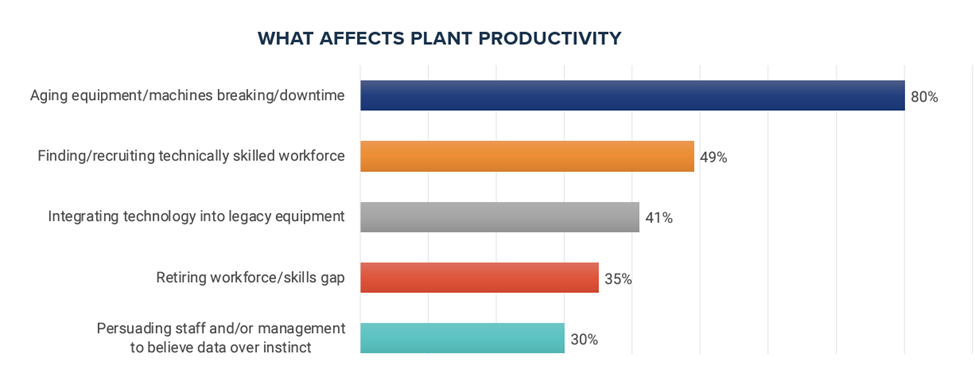

Not only is it a challenge, but 80% cite aging equipment (or machines breaking down and going offline) as the #1 challenge to plant productivity. Not only does equipment downtime affect overall productivity, it will severely impact the supply chain.

These problems persist despite the average plant spending 33 hours each week on scheduled maintenance. Knowing that a problem will arise is one thing, being prepared to address these problems immediately can be the difference between a positive and negative economic outcome. Applying automation and advanced software to maintenance scheduling will produce immediate value to the enterprise.

Continue reading “7 Maintenance Scheduling Mistakes to Avoid”